Inventory Maintenance

Covers BOM Groups, Categories, Dangerous Goods, Docks, Facilities, Facility Groups, Formulators, Item Pictures, Item Planners, Item Search 1–5, Location Types, Locations, Part Exclusions, Reason Codes, Sub-Categories, Units of Measure, and Zones.

BOM Groups

Bill of Material (BOM) Groups, selectable on BOM Lines within Bills of Material, allow users to distinguish different BOM lines by group and are used for end-user organizational and sorting purposes. Users with access to the Inventory — Maintenance setting can create or modify BOM Groups.

System Navigation

- Inventory > Maintenance > BOM Groups

Edit BOM Group

Opened via the New or Modify buttons on the BOM Groups form.

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the BOM Group. |

|

Active |

If checked, this record is active. Only active records may be used. |

Categories

Inventory Categories group items that share similar characteristics and are useful for inventory reporting. Categories are also criteria for Deal Pricing, Promotions, and Commissions in Sales Maintenance. Only one Category may be assigned to an inventory item. The list can contain an unlimited number of entries.

System Navigation

- Inventory > Maintenance > Categories

Edit Category

Opened via the New or Modify buttons on the Categories form.

General tab

|

Field/Flag |

Description |

|---|---|

|

Features (requires Sales Configurator) |

Opens the Features form to manage sales features for this Category. Features are option groups used by the Product and Sales Configurator. |

|

Name |

Unique name of the Category. |

|

Sales Quota |

Planned annual sales in dollars; available in Sales > Order Reporting Ranking. |

|

Active |

If checked, this record is active. |

|

Default |

If checked, used as the default when creating new items. |

|

Restricted Selling |

If checked, marks this as a restricted Category. (Inventory Sub-Categories and Item Search 1–5 can also be restricted.) |

Units tab

Define minutes required per unit to receive/ship items in this Category; used with the Dock calendar for scheduling.

Note: Unit minutes can also be defined on Units of Measure, Item Masters, and Sub-Categories; the system applies a hierarchy.

|

Field/Flag |

Description |

|---|---|

|

Unit of Measure |

Select the UOM. |

|

Receiving Minutes |

Minutes required to receive the UOM for items in this Category. |

|

Shipping Minutes |

Minutes required to ship the UOM for items in this Category. |

Features (requires Sales Configurator)

Opened via the Features button on Edit Category. Lists Features added to the Category.

|

Control |

Description |

|---|---|

|

Add |

Open Edit Feature to add a Feature to the Category. |

|

Remove |

Remove the selected Feature. |

|

Move Up/Down |

Change the listed order as shown on Sales Orders using the Configurator. |

Edit Feature

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Feature. |

|

Description |

Optional text description. |

|

Active |

If checked, the Feature is active. |

|

Sequence |

Numeric order on the Sales Order (lower numbers show first). |

|

Default |

Set as default selection for this Category (one default per Category). |

|

Pricing Factor |

Numeric value used in price calculation when configured. |

|

Commissionable |

If checked, commissions can be earned. |

|

Picture / Select Picture / Remove Picture |

Manage an associated image (JPG or PNG). |

|

Feature Endpoints |

Manage specific selectable options (e.g., color “Red”, “Blue”). Use Add/Remove. |

Feature Endpoints

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique within the Feature. |

|

Active |

If checked, endpoint is active. |

|

Default |

Default endpoint for this Feature (one allowed). |

|

Price |

Specific price for this endpoint when configured. |

|

Active From/To |

Optional active date range. |

|

Commissionable |

If checked, eligible for commission. |

|

Active Code |

Optional code and date range. |

|

Color |

Color value, if applicable. |

Pricing tab (Edit Feature)

|

Field/Flag |

Description |

|---|---|

|

Price |

Base/override price for the Feature. |

|

Price Adjustment Method |

How the Price affects order pricing (e.g., Add, Override, Discount). |

|

Commission % |

Commission percentage, if applicable. |

|

Endpoint Pricing |

Per-endpoint pricing table. |

Availability tab (Edit Feature)

|

Field/Flag |

Description |

|---|---|

|

Availability Group |

Restrict availability by group. |

|

Availability Dates |

Optional start and end dates. |

|

Dependencies |

Rules/requirements for selection. |

Commissions tab (Edit Feature)

|

Field/Flag |

Description |

|---|---|

|

Commissionable |

Marks Feature as commission-eligible. |

|

Commission Code |

Commission code if used. |

|

Commission Exemption |

Exclude from standard commissions. |

Item Search 1–5

Item Search fields (1–5) provide additional categorization beyond Categories and Sub-Categories for custom grouping, filtering, and searching. Users with Inventory Maintenance access can create and modify selections for Item Search 1–5.

System Navigation

- Inventory > Maintenance > Item Search 1–5

Edit Item Search

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Item Search entry. |

|

Active |

If checked, this record is active. |

|

Default |

Default selection for its Item Search field on new items. |

|

Restricted Selling |

If checked, this Item Search field is restricted. (Sub-Categories and Item Search fields may also be restricted.) |

Sub-Categories

Sub-Categories provide additional grouping within a Category. Only one Sub-Category may be assigned per item. Users with Inventory Maintenance access can create and modify Sub-Categories.

System Navigation

- Inventory > Maintenance > Sub-Categories

Edit Sub-Category

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Sub-Category. |

|

Active |

If checked, this record is active. |

|

Default |

Default Sub-Category for new items. |

|

Restricted Selling |

If checked, this Sub-Category is restricted. (Sub-Categories and Item Search 1–5 may also be restricted.) |

Dangerous Goods

Designate items as dangerous/hazardous and provide classifications for handling, shipping, and compliance.

System Navigation

- Inventory > Maintenance > Dangerous Goods

Edit Dangerous Goods

General tab

|

Field/Flag |

Description |

|---|---|

|

UN Number |

Official UN identifier. |

|

Proper Shipping Name |

Official shipping name. |

|

Hazard Class |

Hazard class (e.g., Class 3). |

|

Packing Group |

Packing group (I, II, III), if applicable. |

|

Quantity Limitations (Passenger) |

Limits for passenger aircraft/rail. |

|

Quantity Limitations (Cargo Only) |

Limits for cargo aircraft. |

|

ERG Number |

Emergency Response Guide reference. |

|

Active |

If checked, record is active. |

|

Default |

Default Dangerous Goods entry on new Item Masters when applicable. |

Classification tab

|

Field/Flag |

Description |

|---|---|

|

Class Code |

Additional classification code. |

|

Subsidiary Risk |

Additional risk classes. |

|

Marine Pollutant |

If checked, marked as marine pollutant. |

|

Reportable Quantity (RQ) |

Reportable quantity threshold. |

|

Technical Name |

Technical name if required. |

Docks

Dock records define doors/bays for receiving and shipping. Docks can be associated with Facilities and scheduling parameters.

System Navigation

- Inventory > Maintenance > Docks

Edit Dock

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Dock. |

|

Facility |

Facility to which the Dock belongs. |

|

Dock Calendar |

Calendar controlling scheduling availability. |

|

Active |

If checked, record is active. |

|

Default |

Default Dock for the associated Facility. |

Facilities

Facilities represent physical or logical locations (plants, warehouses, DCs) where inventory is stored, produced, or shipped. Facility records store addresses and settings that affect transactions and processes.

Use Cases

- Transfer Facilities — For Inter-Company Transfers. If specified on a Ship-to Company, new Sales Orders default to Order Type “Inter-Company Transfer”.

- Hold Facilities — Used in transfer-and-hold purchasing; may be specified on a Ship-to Location.

- Invoicing Facilities — For Cross-Facility Orders. If specified on a Ship-to Company, new Sales Orders default to Order Type “Cross-Facility”.

- When running a facility-filtered MRP: if an item is not manufacturable in the facility, Deacom will not explode its BOM for that facility’s run.

System Navigation

- Inventory > Maintenance > Facilities

Edit Facility

Opened via the New or Modify buttons on the Facilities form.

General tab

|

Field/Flag |

Description |

|---|---|

|

Validate Address |

Validates the Facility address (used with FedEx/UPS). Saving triggers validation if enabled in Sales > Options (Automatically Validate Address). Added in 17.03.009. |

|

Name |

Unique Facility name. |

|

Street/Street 2 |

Address lines. |

|

City, State, Zipcode, Country |

Location details. |

|

Phone |

Required for FedEx with address fields. |

|

Country Code |

Phone mask selection if required. |

|

Global Location Number |

GLN (GS1 13-digit) if required. |

|

Currency |

Override Facility currency for booking transactions (inventory, labor, burden, etc.). Also adds currency context to Item/Ffacility costs, rollups, transactions, warnings on cross-currency postings, and currency filters on reporting. |

|

Fax |

Facility fax, if applicable. |

|

Emergency Contact |

Contact name for emergencies. |

|

Negative Inventory |

Overrides Item Master setting for this Facility:

|

|

Print Substitutions |

Select a Print Substitution Group for forms printed when this Facility is used. |

|

Active |

Marks the Facility as active. |

|

Default |

Default Facility where a Facility field exists. |

|

Prevent Inventory Transactions |

Prevents transactions other than physical inventory postings (use during counts). Also exists on Item Master, Item Master Facility, Location Type, and Location. Note: the Physical Inventory Forms option “Automatically Prevent Included Item Transactions” can bulk-prevent transactions faster than item-by-item flags. |

|

Transfer Hold Lot Control |

Enforces lot control on second receipt of a Transfer Hold PO; maintains QC tests and allows catch weight on initial receipt when used. |

APIs tab

Note: Starting in 17.03, API profiles are managed via the API Profiles form (FedEx, UPS, EasyPost, sales tax, QuickBooks Online, USPS).

Sales tab

|

Field/Flag |

Description |

|---|---|

|

IC Xfer Markup Type |

Determines costing for Inter-Company Transfer receipts into this Facility and for Cross-Facility invoicing:

For ICTs, invoice date populates with receipt date for types other than Ship and Hold. |

|

Markup Factor |

Percentage or dollar amount applied with the selected Markup Type. Additive with Item Master “IC Trans Markup %”. A factor of 0% transfers at cost. |

|

Incremental Reserve |

Controls incremental reserving/staging in WMS:

|

|

ICT Receipt Qty |

|

|

Automatically Receive ICT |

Auto-receive ICTs to this Facility. Put-away logic checks: Item Master Facility Default Location > Item Master Default Location > Facility’s default LocationType/Location. Prompts if setup is missing. |

|

Allow Inter-Co. Transfer To Facility |

Allows this Facility to receive ICT shipments. |

|

Retain Inter-Co. Transfer Location |

Keeps Location/Type from shipping Facility if they exist; else uses receiving defaults. Useful for “customer-owned” Facilities. |

|

Custom Part First When Reserving ICT in WMS (requires WMS) |

Auto-opens lot picker for custom parts when reserving ICTs in Reserve SO. |

|

Finish Linked Job Upon Shipment |

Automatically finishes quantities on linked Jobs when shipping SOs, Cross-Facility Orders, and ICTs. Requires Allow Inter-Co. Transfer To Facility and appropriate co-packer setup. Generates user lots for shipped lot-tracked items. |

|

Ship on Save (requires WMS) |

Default value for the WMS Reserve SO “Ship on Save” flag. |

|

Don’t Require Lot Tracking on DSD |

Skips specific lot selection for DSD shipments; uses FIFO for lot-tracked items. |

|

POS Default Bill-to (requires POS) |

Default Bill-to Company for POS at this Facility. |

|

CC Processor |

Select credit card processor used for this Facility. Hierarchy: Bill-To Company > Facilities > System Default. |

|

Default Shipping Qty |

Facility-level default shipping quantity (overrides System Options, below Item level):

Note: Item Master General 2 also has a Default Shipping Qty; “Default” there defers to this Facility setting. |

|

Retain Lot Costs on IC Xfer |

Receive lots at current cost (no markup to inventory). Markup posts to revenue and is balanced to a markup account. |

|

Override TaxJar Address with Facility |

Swaps Facility and ship-to addresses when both are in the same state (TaxJar). |

|

Prompt When Over Reserving |

Always prompt yes/no when over-reserving/staging. Checked by default; applies to main app and WMS. |

Production tab

Production-specific Facility settings (fields vary by implementation).

Facility Groups

Group multiple Facilities for reporting or processes (e.g., regional groups or by function).

System Navigation

- Inventory > Maintenance > Facility Groups

Edit Facility Group

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Facility Group. |

|

Active |

If checked, record is active. |

|

Facilities in Group |

Add/Remove Facilities; a Facility can belong to multiple groups. |

Formulators

Designate individuals/entities responsible for formulations (useful in regulated industries).

System Navigation

- Inventory > Maintenance > Formulators

Edit Formulator

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name. |

|

Active |

If checked, record is active. |

|

Default |

Default selection on new formulations/product records. |

Item Pictures

Manage images associated with inventory items (e.g., display on Sales Orders or picking tickets).

System Navigation

- Inventory > Maintenance > Item Pictures

Edit Item Picture

|

Field/Flag |

Description |

|---|---|

|

Item |

Select the inventory item. |

|

Picture |

Displays current picture (if any). |

|

Select Picture |

Upload image (JPEG/PNG). |

|

Remove Picture |

Remove current image. |

|

Description |

Optional notes. |

|

Active |

If checked, record is active. |

Item Planners

Assign planning responsibility (purchasing/production) to a person/role; useful for filtering reports/workflows. Users with Inventory Maintenance access can add/modify Item Planners.

System Navigation

- Inventory > Maintenance > Item Planners

Edit Item Planner

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique planner name (person or role). |

|

Active |

If checked, record is active. |

|

Default |

Default planner on new Item Masters. |

|

User ID |

Link to system user, if applicable. |

Location Types

Define categories of storage locations (e.g., Warehouse, Production Floor, In-Transit) to apply rules/defaults. Names can be changed without breaking links (the system uses internal IDs).

System Navigation

- Inventory > Maintenance > Location Types

Edit Location Type

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Location Type. |

|

Active |

If checked, record is active. |

|

Default |

Default type when creating new Locations. |

|

Prevent Inventory Transactions |

Prevents transactions (other than physical inventory postings) for Locations of this type. Use during counts. Also exists on Item Master, Facilities, Locations, and Zones. |

Locations

Define specific storage places within a Facility (warehouse, aisle, bin, etc.). Each Location is tied to a Location Type and a Facility. Names can be renamed safely (links use IDs).

System Navigation

- Inventory > Maintenance > Locations

Edit Location

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique within the Facility context. |

|

Facility |

Facility to which this Location belongs. |

|

Location Type |

Classification for the Location. |

|

Default Location |

Marks as default for its Location Type in the Facility (one per type per facility). |

|

Active |

If checked, record is active. |

|

Prevent Inventory Transactions |

Prevents transactions (other than physical inventory postings) for this Location. Used during counts. |

Part Exclusions

Restrict items from being sold to certain customers/groups or regions. The security setting Sales orders — override restricted selling allows viewing/selecting restricted items with a prompt.

System Navigation

- Inventory > Maintenance > Part Exclusions

Edit Part Exclusion

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the exclusion rule/group. |

|

Active |

If checked, record is active. |

|

Default |

Default exclusion where applicable. |

|

Excluded Parts |

List of parts/items excluded by this rule. |

|

Excluded Customers |

Customers or groups to which this applies (if applicable). |

|

Notes |

Optional notes. |

Put Away Rules

Companies can use Put Away Rules to dictate how inventory can be physically put away in a warehouse. These rules may then be used for a company to automatically determine the nearest suitable Location in which they can put away a given item. Utilizing the Put Away Rule framework, companies will be able to create a rule for a given Part Number, choose specified Location overrides (if they need to stack an item lower than a Location would normally allow, for instance), specify the sort methodology they wish to use, set Existing Inventory to Same Part Number so that only like parts may go together in a non-empty Location, set Lot Number to Same so that only like Lots may go together in a non-empty Location, etc.

Additional features allow companies to apply this rule to not just a single Part, but to a Sub-Category, Category, Item Search 1-5 field, or all Parts for easy setup. There is also the ability to allow/disallow placing an item in a Location based on the Inventory Segment or QC Status of items already in place. These rules will apply real-time in the WMS system and once set up, require no intervention from the user other than an item scan.

Once the fields of the form are set - specifically, the "To Type" and "Facility/Location/Location Type" fields - the Location Sort section of the form will populate with the Locations deemed valid by the warehouse hierarchy defined in the system. For example, if a Put Away Rule is configured for a Facility, then the rule will apply to all Locations that belong to that Facility. If a Put Away Rule is configured for a specific Location, then the rule will only apply to that Location, but not be limited to only that Location within one Facility or Location Type. This is helpful in situations where one Location, such as a Freezer, exists in multiple Facilities, and the same Put Away Rule should apply to all Freezers.

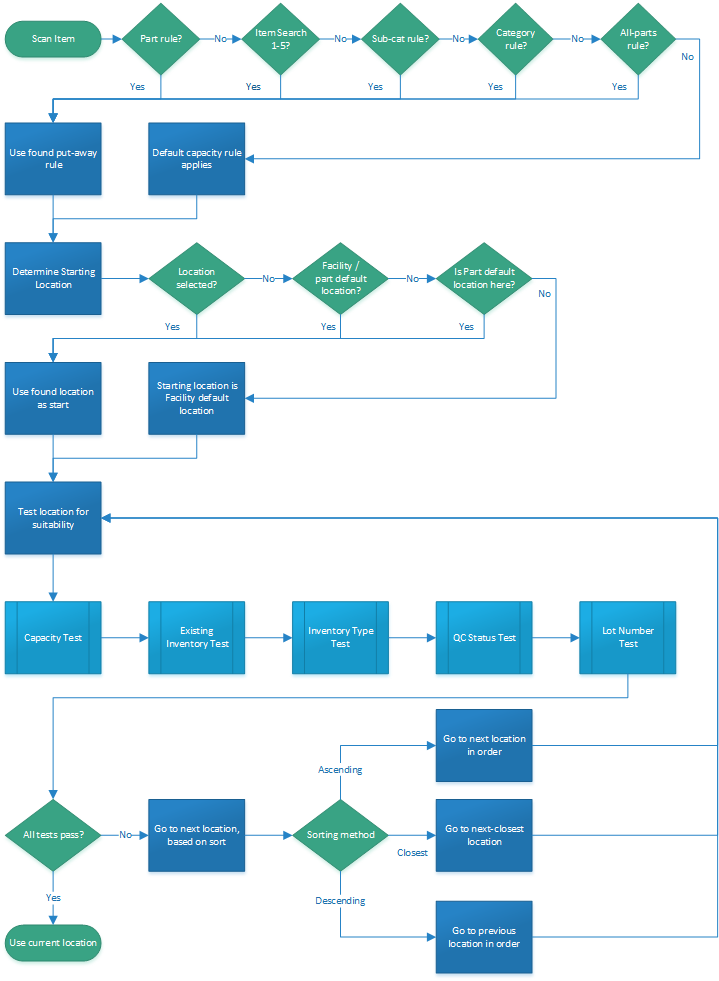

Put away location suggestion logic

Once Put Away Rules are created, the put away location suggestion logic fundamentally consists of checking a Location for suitability with a number of disqualifying tests. Once Deacom finds a Location to potentially use, and if that Location passes all tests, then it is used as the put away location. If it fails any test, then the logic proceeds to the next possible Location and repeats the tests. A visual representation of this process is also included for reference. Note: For all sorting behaviors described below, Locations are first sorted by the Location Sequence number. If there is a tie, they are then sorted by the Location's Name.

Location suitability check

- Check for relevant rule:

- The system determines if there is a relevant Put Away Rule specifically for the Part Number being put away (i.e. a Put Away Rule with a "For Type" of "Part Number" and "For" with that Part Number's ID). If such a rule exists, it is used.

- If no such rule exists, the system looks for a Put Away Rule for the Part Number's Item Search 1-5 field (i.e.a Put Away Rule with a "For Type" of one of the Item Search 1-5 fields and with that fields Item Search ID). If such a rule exists, it is used.

- If no such rule exists, the system looks for a Put Away Rule for the Part Number's Sub-Category (i.e. a Put Away Rule with a "For Type" of "Sub-Category" and "For" with that Part Number's Sub-Category ID). If such a rule exists, it is used.

- If no such rule exists, the system looks for a Put Away Rule for the Part Number's Category (i.e. a Put Away Rule with a "For Type" of "Category" and "For" with that Part Number's Category ID). If such a rule exists, it is used.

- If no such rule exists, the system looks for a Put Away Rule for "All Part Numbers". If such a rule exists, it is used.

- If no such rule exists, the system follows the logic in "Default Behavior" described below.

- Determine starting Location:

- If the form being used to move/receive material contains a "Location" field that is populated, the Location is used.

- If no such field exists, the system checks for Locations in the Location Sort section of the Put Away Rule. If one or more are found, the Location with the lowest Sequence number is used.

- If no such records exist, the system looks for the "Default Location" selected on a Facility Part Cross Reference for the Facility and Part selected, if one exists. If one is found, it is used.

- If no such records exist, the system looks for the "Default Location" selected on the Part's Item Master General 1 tab. If one is specified and belongs to the current Facility, it is used.

- If no such default exists, the system looks for the current Facility's default Location Type then looks for that Location Type's default Location. That Location is then used as the starting Location.

- Default Behavior (no applicable Put Away Rule was found):

- The system finds the closest Location with available capacity. Beginning with the starting Location, the system determines if that Location has enough available capacity. If it does, that Location is used as the recommended put away location.

- If that Location does not have sufficient capacity, the system checks the Location one below the starting Location. If that Location has enough available capacity, it is used.

- If that Location does not have sufficient capacity, the system checks the Location one above the starting Location (therefore two above the previous Location checked). If that Location has enough available capacity, it is used.

- If that Location does not have sufficient capacity, the system continues with the following pattern, where "start" indicates the starting Location: [start], [start] -1, [start] + 1, [start] -2, [start] + 2, [start] -3, etc. until a suitable Location is found and returned.

- If no suitable Location is found, the system will prompt the user.

- Directed Put Away Behavior (an applicable Put Away Rule was found):

- The system finds the closest Location with available capacity. Beginning with the starting Location, the system determines if that Location has enough available capacity. If it does, that Location is used as the recommended put away location.

- If that Location does not have sufficient capacity, the system uses the "Sort" pattern selected on the Put Away Rule (described in the "Sort" field description below) to check each Location from the relevant list of Locations found for sufficient capacity.

- Determine list of relevant Locations:

- If there are Locations listed in the Location Sort section of the Put Away Rule being used, those records and corresponding Sequences are used as the list of relevant Locations. If one or more are found, the Location with the lowest Sequence number is used.

- If there are no Locations listed in the Location Sort section of the Put Away Rule being used, the system uses the list of active Locations, found in Inventory > Maintenance > Locations, and their corresponding "Location Sequence" values.

- When each Location is checked, all of the following disqualifying tests are run. If the Location passes all tests, it is used as the recommended put away Location. If not, the system continues on to the next Location using the above logic.

Disqualifying tests

- "To" test:

- If this Location resides within the "To" place as defined in "To Type" and "To" fields on the Put Away Rule, then this test passes.

- "Capacity" test:

- If "Capacity Type" is set to "Amount" on the applicable Put Away Rule, then use the capacity values from that rule for the Location Capacity for the calculation specified below.

- If "Capacity Type" is set to "Percent", then multiply the "Capacity" defined on the Location record by the "Capacity" value defined on the rule and divide by 100. Use this value for the Location Capacity.

- If "Capacity Type" is set to "From Location", then use the maximum capacity of the Location for this test, defined by the "Capacity" field on the Location record: Take everything already in this Location, and convert the item quantities to the Location's defined "Capacity Unit", then sum. Location capacity minus this value is remaining capacity. Determine capacity value of quantity to be put away by converting capacity units. If this value is less than or equal to remaining capacity, then the material can be placed in this Location and this test passes.

- "Existing Inventory" test:

- If "Existing Inventory" is set to "Any" on the applicable Put Away Rule, then this test passes.

- If "Existing Inventory" is set to "None", then this Location only passes if it has no inventory in it already.

- If "Existing Inventory" is set to "Same Category", then this Location only passes if (1) all inventory already in it belongs to the same Category as the Part Number being put away or (2) it is empty.

- If "Existing Inventory" is set to "Same Sub-Category", then this Location only passes if (1) all inventory already in it belongs to the same Sub-Category as the Part Number being put away or (2) it is empty.

- If "Existing Inventory" is set to "Same Part", then this Location only passes if (1) all inventory already in it is the same Part as the Part Number being put away or (2) it is empty.

- "Inventory Type" test:

- If "Inventory Type" is set to "Any" on the applicable Put Away Rule, then this test passes.

- If "Inventory Type" is set to "Same", then this Location only passes if (1) all inventory already in it is part of the same inventory segment as the Part Number being put away (2) it is empty.

- "QC Status" test:

- If "QC Status" is set to "Any" on the applicable Put Away Rule, then this test passes.

- If "QC Status" is set to "Same", then this Location only passes if (1) all inventory already in it has the same QC Status as the Part Number being put away or (2) it is empty.

- "Lot Number" test:

- If "Lot Number" is set to "Any" on the applicable Put Away Rule, then this test passes.

- If "Lot Number" is set to "Same", then this Location only passes if (1) all inventory already in it has the same Lot Number as the Part Number being put away or (2) it is empty.

- If all tests pass, then return this as the recommended put away location. If not, the system continues on to the next Location using the logic described earlier.

System Navigation

- Inventory > Maintenance > Put Away Rules

Edit Put Away Rule form

Opened via the "New" or "Modify" buttons on the Put Away Rules form.

|

Button/Field/Flag |

Description |

|

Same As |

Allows the user to use a previously created Put Away Rule as a base for a new one. |

|

For Type |

Pick list used to determine to what the rule applies. Options are:

|

|

Category/Part Number/Sub-Category/Item Search 1-5 |

Search field used to select the applicable Category, Part Number, Sub-Category or Item Search 1-5 that this rule applies to.

|

|

To Type |

Pick list used to determine where the rule applies.

|

|

Facility/Location/Location Type |

Search field used to select the applicable Facility, Location, or Location Type that this rule applies to.

|

|

Capacity Type |

Pick list used to determine if the rule is subject to a specific capacity, and if so whether the capacity limit is amount from location, a specific absolute amount for this rule, or a percentage of total location maximum capacity.

|

|

Capacity Unit |

The Unit in which the "Capacity" is measured, when "Capacity Type" is set to "Amount". |

|

Capacity |

The specific absolute amount or percentage of total location maximum capacity that may be consumed by the material. |

|

Active |

If checked, this record is active. Only active records may be used in the system. |

|

Fill Partial Location Prior To Empty Location |

If checked, the system will look for and suggest to fill a location that meets both of the two criteria below.

In this case, the system will attempt to fill the location to capacity before trying to fill closer locations. This flag is unchecked by default. |

|

Sort |

Pick list used to determine how Locations are sorted when the system is iterating through the options to suggest one for use. Options are:

|

|

Existing Inventory |

Pick list used to determine if the material being received/moved can be mixed in with other Parts, or segregated based on Category, Sub-Category, etc. Options are:

|

|

Inventory Type |

Pick list used to determine if the material being received/moved can be mixed in with material classified as a different Inventory segment. Options are:

|

|

QC Status |

Pick list used to determine if the material being received/moved can be mixed in with material classified as a different QC status. Options are:

|

|

Lot Number |

Pick list used to determine if the material being received/moved can be mixed in with material labeled with a different Lot Number. Options are:

|

|

Sort |

Allows the user to sort the order in which the available Locations, as listed in the Location Sort section of the form, are suggested when a user is putting away inventory. |

Quality Control Groups

Quality Control is a major method of providing process control within Deacom. Quality Control ensures that required Quality Control Tests are performed when Raw Materials are received on Purchase Orders, when Finished Goods are produced on production Jobs, and when previously sold products are returned. Quality Control is an optional feature with a wide array of applications ranging from completely turned off to extremely strict requirements, and is established on an item by item basis. This means that some items can have absolutely no quality control, while others can have many required QC tests.

Quality Control Tests are required to do QC testing. The Quality Control Test describes the base name of the test as well as any applicable testing methods and the Unit of Measure that should be used for testing. Quality Control Groups are a list of sequenced Quality Control Tests for the group to perform. QC Groups can be attached to a Part's Item Master to indicate testing required upon PO receipt or on a Bill of Materials to indicate testing required prior to, or following, finishing of material on a production Job. If two items have identical QC Tests and allowable results, they can share the same QC Group. If two items have different QC Tests or different allowable results, they would each have a different QC Group. A system can have as few as one QC Group, or as many QC Groups as there are items, or anything in between. Items may also have multiple QC Groups assigned based on different testing levels. For example, all Raw Materials may be assigned a basic QC Group, with a certain sub set of Raw Materials being assigned an additional QC Group on the Item Master record to ensure these materials undergo additional QC testing requirements.

Quality Control Security Groups are assigned to each Quality Control Test when the test is added to a Quality Control Group. User Groups are then assigned to QC Security Groups using Quality Control Group Security. This grid must be updated whenever a new Quality Control Security Group or User Group is created to ensure the new group has appropriate access. Specific test protocols and security for entering QC data are configured via Quality Control Groups and security for who can enter QC values is configured via Quality Control Security Groups. Additional system security is required to perform functions such as creating or modifying QC Tests and QC Security Groups.

QC approval process and security options

Quality control results may be entered without requiring approval before users may click the "Finish QC" button and place items into regular inventory or failed QC inventory. The QC approval process involves the ability to review and indicate final approval for those QC groups that require this check and also the ability to approve individual QC results that are out of spec for manufactured items. Several different security options and features are available to ensure QC results are validated.

General QC approval

The ability to require QC approval is determined by the "Approval Type" field on the QC Group. If this field is set to any value other than "None", a separate approval step is required in addition to entry of test results to indicate final approval or rejection of the tested material. In addition, users will be unable to use the "Finish QC" button when performing testing until the "Approve QC" flag has been checked on the Quality Control Results form. Security exists to control access to Approve QC.

E-Signature approval

The "Require E-Signature For Approval" and "Require E-Signature For Results" flags are available to each Quality Control Group. If checked, a valid Deacom username and password is required to be entered before the “Finish QC” step is allowed or before a QC pass may be entered. A record of this approval is stored in Deacom in an encrypted record (AES-256 encryption like the rest of the system). The Deacom application complies with the FDA requirement (21 CFR 11) for E-Signatures by employing at least two distinct identification components, namely a username and password as indicated in Section 11-200 of the Code of Federal Regulations. Note: Multiple e-signatures may be required for each QC pass via the "e-Signature Counts" fields.

Approving out of spec QC results

A QC result is considered within specification if the result is between the minimum and maximum values defined on the test. The "Must Pass QC To Continue" flag is an optional setting located on each QC item within the QC group. If this flag is checked, the QC result must be between the minimum and maximum values before the material can be accepted into regular inventory. Security exists that allows users to approve QC results when the results are out of specification. This security is used in connection with the Approve QC security mentioned above.

System Navigation

- Inventory > Maintenance > Quality Control Groups

Edit Quality Control Group form

Opened via the "New" or "Modify" button on the Quality Control Groups form, the Edit Quality Control Group form is used to group together Quality Control Tests that should be performed on a given Part. Information pertaining to the group is configured using the General and User Fields tabs and all QC Tests belonging to the group are listed on the bottom of the form. A couple notes regarding QC Groups include:

- The "un_name" column, which displays the QC Unit of Measure (if populated) is available to this form.

- The "Require E-Signature When Saving A QC Group" flag on the Inventory > Options > QC tab will prompt and require a user to enter valid credentials before modifying a QC Group.

- When modifying an existing QC group, including QC tests on the group, the system checks to see if there are open jobs using this QC Group or if there are lots in Pending QC using this QC Group that have QC values already entered.

- If open jobs are found with the QC Group, the system will prompt users asking if they wish to the update the QC Group on these jobs.

- If there are lots in Pending QC using this QC Group that have existing QC values, then the system will list the affected lots, and prompt users that these lots will have their QC values removed and if they wish to Continue. If users choose to continue, QC values will have to be reentered for the affected lots.

|

Button |

Description |

|---|---|

|

Same As |

Allows the user to copy an existing Quality Control Group to use as a base for the one being created.

|

|

Add |

Opens the Edit Quality Control Item form, which is used to add a Quality Control Test to the group and assign values and other qualities. |

|

Modify |

Opens the Edit Quality Control Item form, which is used to modify the selected Quality Control Test. |

|

Delete |

Deletes the currently selected Quality Control Test. |

|

Sort |

Allows the user to sort the order of the Quality Control Tests listed. |

General tab

|

Field/Flag |

Description |

|---|---|

|

QC Group Name |

Defines the name of the group. |

|

Days Open |

Indicates the number of days after production that QC entry is allowed. |

|

Approval Type |

Pick list used to indicate when and how approval is required. Options are:

Approval overrides failed tests that are flagged as “Must Pass QC To Continue”. Rejection sends material into Failed QC status, where only approved users have access to it. |

|

E-Sig Approval Type |

Pick list used to indicate when and how E-Signatures are required.

|

|

QC Approval E-Signature Counts |

Only used when approving QC to determine how many e-signatures are required. Option to require, and store, multiple e-signatures when approving QC. If the number in this field is greater than 1, the system will display a signature form, requiring an entry, for the number specified in this field.

|

|

QC Results E-signature Counts |

Used to determine how many e-signatures are needed to enter results.

|

|

Active |

If checked, this record is active. Only active records may be used in the system. |

|

Default |

This flag is not used for Quality Control Groups and therefore has no purpose if checked. It is listed only because it is a standard field on forms. |

|

Complete Empty Tests |

If checked, the system will complete empty tests with empty values and move them to QC list/values form. If not checked, the system will only move tests that have values to the QC list/values form.

|

|

Require E-Signature For Approval |

If checked, a valid Deacom username and password is required to be entered before the “Finish QC” step is allowed.

|

|

Require E-Signature For Results |

If checked, a valid Deacom username and password is required to be entered when applying each pass of QC results.

|

|

Do QC After Production |

If checked, QC is performed after production.

|

|

Approval Required |

If checked, approval is required for the QC results to be posted. |

|

Copy Vendor/Pre-Production QC |

If checked, and the “Retain QC” field on the Vendor's General tab is set to “Same Part” or “All”, then the system will automatically populate the QC results when receiving the sameUser Lot for items from this Vendor.

|

|

Fail To Quarantine |

If checked, Lots that fail QC testing will automatically be failed to the Quarantine inventory segment.

|

User Fields tab

Deacom allows the creation of user-defined fields that, once created, are available on various master data records such as items, Vendors, and Ship-to Companies. These fields allow companies to enter and store information outside of the fields provided in the system. User fields may be added via Tools > Tools Maintenance > User Fields.

- Note: QC Test user fields can be added to the Edit Quality Control form

Work Flow tab

Work Flows, managed via Tools > Maintenance > Work Flows, that are assigned to a QC Group are the associated Sequences that must be completed before it is considered complete. This requires the permission "Quality control -- edit QC Group work flow level 0-9" in Edit User Access to add a Work Flow to a QC Group. A search box with applicable Work Flows allows the user to add the desired Work Flow to the QC Group.

Edit Quality Control Item form

Opened via the "Add" or "Modify" buttons on the Edit Quality Control Group form, the Edit Quality Control Item form is used to manage Quality Control Tests within a Quality Control Group and assign values and other qualities. A few notes regarding the values specified in this form:

- The "Min Value" must be less than the "Max Value", unless the max is 0.

- Tests may be created with a minimum and no maximum, in which case QC results will pass if the result is greater than the minimum and the maximum is set to 0.

- Example: Assume a test has a minimum of 10 and a maximum of 0. The system will enforce only that the result must be greater or equal to the minimum.

- Numbers must be used to accommodate situations where a test result needs to be expressed as "Yes" or "No", "True" or "False", or "Pass" or "Fail".

- In these cases, 0 represents no/false/fail and 1 represents yes/true/pass.

- To enable this option, users may set the minimum and maximum values both to 1.0, in which case 1.0 means yes and any other value means no.

- A "9" may also be added to the "Input Mask" field to ensure only one number is entered for the test result.

|

Field/Flag |

Description |

|---|---|

|

Quality Control Test |

Search field used to select a Quality Control Test to add to the group. |

|

QC Test Group |

Search field used to select the Quality Control Security Group that applies to this test. |

|

Description |

Displays a description of the test, up to 200 characters. |

|

Target Value |

Memo field used to indicate the target value for the test.

|

|

Default Value |

Optional, set the default QC Test value in a QC Test setup which will populate by default. Useful if have many simple/optional QC Tests to lessen the burden of entry. |

|

Min Value |

Indicates the minimum accepted value for the test. |

|

Max Value |

Indicates the maximum accepted value for the test. |

|

Min Detectable |

Indicates the default value for a minimum detectable reading, generally used for legal requirements.

|

|

Print Mask |

Field used for formatting the QC results on forms. When the Print Mask is not used, the Input Mask will be the fallback field used for formatting the QC Results on forms. Input Mask and Print Mask can be used together when users should enter results with 4 decimals, but only display 3 decimals.

|

|

Input Mask |

Defines the mask, which governs the format, that will be used when entering the results.

|

|

Aggregate Type |

Pick list used to select which QC value, when multiple iterations of a test are performed, will populate on Part Forms. Options are:

|

|

Notes |

Memo field used to store notes regarding the test. |

|

Required |

If checked, a value must be entered for this test prior to moving the item to inventory.

|

|

Must Pass QC To Continue |

If checked, a value entered for this test must be between the minimum and maximum defined.

|

|

Print On Forms |

If checked, the test description, values, and notes will be available for display on Part Forms, including Certificates of Analysis.

|

|

Prints On POs |

If checked, the test description, values, and notes will be available for display on Purchase Orders.

|

|

Require Notes |

If checked, users will be required to enter notes for this test, via the "Edit Notes" button on the Edit QC Results form, before results can be saved/applied.

|

Quality Control Security Groups

Quality Control is a major method of providing process control within Deacom. Quality Control ensures that required Quality Control Tests are performed when Raw Materials are received on Purchase Orders, when Finished Goods are produced on production Jobs, and when previously sold products are returned. Quality Control is an optional feature with a wide array of applications ranging from completely turned off to extremely strict requirements, and is established on an item by item basis. This means that some items can have absolutely no quality control, while others can have many required QC tests.

Quality Control Tests are required to do QC testing. The Quality Control Test describes the base name of the test as well as any applicable testing methods and the Unit of Measure that should be used for testing. Quality Control Groups are a list of sequenced Quality Control Tests for the group to perform. QC Groups can be attached to a Part's Item Master to indicate testing required upon PO receipt or on a Bill of Materials to indicate testing required prior to, or following, finishing of material on a production Job. If two items have identical QC Tests and allowable results, they can share the same QC Group. If two items have different QC Tests or different allowable results, they would each have a different QC Group. A system can have as few as one QC Group, or as many QC Groups as there are items, or anything in between. Items may also have multiple QC Groups assigned based on different testing levels. For example, all Raw Materials may be assigned a basic QC Group, with a certain sub set of Raw Materials being assigned an additional QC Group on the Item Master record to ensure these materials undergo additional QC testing requirements.

Quality Control Security Groups are assigned to each Quality Control Test when the test is added to a Quality Control Group. User Groups are then assigned to QC Security Groups using Quality Control Group Security. This grid must be updated whenever a new Quality Control Security Group or User Group is created to ensure the new group has appropriate access. Specific test protocols and security for entering QC data are configured via Quality Control Groups and security for who can enter QC values is configured via Quality Control Security Groups. Additional system security is required to perform functions such as creating or modifying QC Tests and QC Security Groups.

System Navigation

- Inventory > Maintenance > Quality Control Security Groups

Edit QC Security Group form

Opened via the "New" or Modify" buttons on the Quality Control Security Groups form.

|

Field/Flag |

Description |

|---|---|

|

Name |

Displays the name of the security group. |

|

Active |

If checked, this record is active. Only active records may be used in the system. |

|

Default |

If checked, this security group is the default for new Quality Control Tests added to Quality Control Groups. |

Quality Control Tests

Quality Control is a major method of providing process control within Deacom. Quality Control ensures that required Quality Control Tests are performed when Raw Materials are received on Purchase Orders, when Finished Goods are produced on production Jobs, and when previously sold products are returned. Quality Control is an optional feature with a wide array of applications ranging from completely turned off to extremely strict requirements, and is established on an item by item basis. This means that some items can have absolutely no quality control, while others can have many required QC tests.

Quality Control Tests are required to do QC testing. The Quality Control Test describes the base name of the test as well as any applicable testing methods and the Unit of Measure that should be used for testing. Quality Control Groups are a list of sequenced Quality Control Tests for the group to perform. QC Groups can be attached to a Part's Item Master to indicate testing required upon PO receipt or on a Bill of Materials to indicate testing required prior to, or following, finishing of material on a production Job. If two items have identical QC Tests and allowable results, they can share the same QC Group. If two items have different QC Tests or different allowable results, they would each have a different QC Group. A system can have as few as one QC Group, or as many QC Groups as there are items, or anything in between. Items may also have multiple QC Groups assigned based on different testing levels. For example, all Raw Materials may be assigned a basic QC Group, with a certain sub set of Raw Materials being assigned an additional QC Group on the Item Master record to ensure these materials undergo additional QC testing requirements.

Quality Control Security Groups are assigned to each Quality Control Test when the test is added to a Quality Control Group. User Groups are then assigned to QC Security Groups using Quality Control Group Security. This grid must be updated whenever a new Quality Control Security Group or User Group is created to ensure the new group has appropriate access. Specific test protocols and security for entering QC data are configured via Quality Control Groups and security for who can enter QC values is configured via Quality Control Security Groups. Additional system security is required to perform functions such as creating or modifying QC Tests and QC Security Groups.

System Navigation

- Inventory > Maintenance > Quality Control Tests

Edit Quality Control Test form

Opened via the "New" or "Modify" buttons on the Quality Control Tests form.

General tab

|

Field/Flag |

Description |

|---|---|

|

Name |

Displays the name of the test. |

|

Test Method |

Describes the approved method to be used for conducting the test. |

|

Unit Of Measure |

Indicates the Unit used to measure test results. |

|

Input Mask |

Defines the mask, which governs the format, that will be used when entering the results. Note: The value entered in this field will provide the default to "Input Mask" field on the Edit Quality Control Item form when adding this QC Test to a Quality Control Group.

|

|

Print Mask |

Field used for formatting the QC results on forms. When the Print Mask is not used, the Input Mask will be the fallback field used for formatting the QC Results on forms. Input Mask and Print Mask can be used together when users should enter results with 4 decimals, but only display 3 decimals. Note: The value entered in this field will provide the default to "Print Mask" field on the Edit Quality Control Item form when adding this QC Test to a Quality Control Group.

|

|

Combine Results |

Option to have the system compare the values for the selected criteria in this field on lots being relived to production jobs and transfer those values to the lot produced on the job. Options are None, Weighted Average, Average, Minimum, and Maximum.

|

|

Active |

If checked, this record is active. Only active records may be used in the system. |

User Fields tab

User Fields provide companies with a useful tool to add additional information or selection options via the use of list boxes to master data records and orders throughout the Deacom system. Users can add QC Test User Fields to the Inventory Quality Control Tests grid and can also add QC Test User Fields to the QC INFO and QC PARENT INFO block types on COA reports, and on other Part Forms, including PO Labels. The information entered in User Fields is also available for printing on many of the printouts and labels throughout the system. When using the QCINFO and QC PARENT INFO blocks for PO labels, the default values from the Item Master QC group/tests will be printed on the label.

User Fields must first be created before they will be visible on this tab.

Reason Codes

Classify why transactions/adjustments occur (e.g., inventory adjustments, cycle count discrepancies). Users with Inventory Maintenance access can create/modify Reason Codes; the list can be unlimited.

System Navigation

- Inventory > Maintenance > Reason Codes

Edit Reason Code

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Reason Code. |

|

Type |

Context (e.g., Adjustment, Scrap, Return). |

|

Active |

If checked, record is active. |

|

Default |

Default in contexts requiring a reason code. |

|

Description |

Optional longer description. |

Units of Measure

Define measurement units (each, box, case, kg, lb, etc.) for stocking, purchasing, and selling, and how they convert.

System Navigation

- Inventory > Maintenance > Units of Measure

Edit Unit of Measure

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique UOM name (e.g., Each, Box, Case, Pound, Kilogram). |

|

Type |

UOM category (e.g., Weight, Volume, Each). |

|

Active |

If checked, record is active. |

|

Base Unit |

Indicates base unit for conversions (if applicable). |

|

Conversion Factor |

Defines conversion to the base (e.g., 1 Box = 12 Each). |

Conversions

If supported, define conversions directly in a table/matrix. Actual UI may use pairwise conversion entries rather than a static matrix.

Zones

Group/categorize Locations within a Facility for workflow or picking (e.g., Cold Storage, Bulk Storage, Zone A).

System Navigation

- Inventory > Maintenance > Zones

Edit Zone

|

Field/Flag |

Description |

|---|---|

|

Name |

Unique name of the Zone. |

|

Facility |

Facility to which the Zone belongs. |

|

Part (Enterprise only) |

Associate a specific part/group (if applicable). |

|

Active |

If checked, record is active. Note: After inactivating Zones, scanner users must re-log to refresh the list. |

|

Default |

Default Zone wherever a Zone field appears. |

|

Prevent Inventory Transactions |

Prevents transactions (other than physical inventory postings) for this Zone. Also exists on Item Master, Facilities, Locations, and Location Types. The Physical Inventory Forms option can bulk-prevent transactions faster than item-level flags. |

Locations in Zone

Use Add/Modify to assign Locations to the Zone.

|

Field |

Description |

|---|---|

|

Location |

Select the Location(s) belonging to this Zone. Blank is not allowed, but a Location named “None” is valid if used as a placeholder. |